Homepage of Stefan Salewski

A footprint generator for the free PCB tool of the gEDA collection

If you have a schematic of an electronic device and want to build a real device out of it you usually make a PCB -- a printed circuit board. Usually this board is first populated with "footprints" or "land patterns" which are needed for mounting the electronic devices like resistors, transistors, operational amplifiers and so on. The PCB-program of the gEDA collection of free software tools for Electronic Design Automation (EDA) is shipped with a large collection of footprints -- many more are available freely in Internet, i.e. at gedasymbols.org or at John Luciani's footprint page.

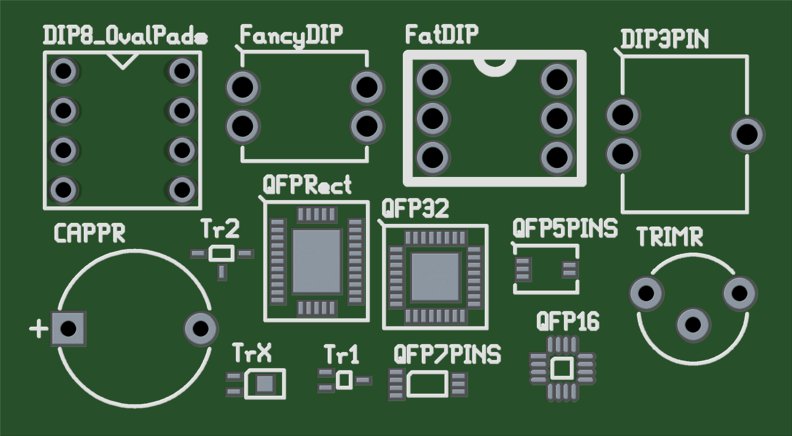

But sometimes one is missing, or you need a special kind of it. So you have to make your own. For PCB this is not too difficult -- the footprints are defined in textual form, which can easily be modified with a text editor. For creation of new footprints different tools exist, some which are command line driven, some with a graphical or web based interface. On this page yet another one is available -- command line based and written in Ruby. Here are a few arbitrary footprints which are built for some testing of this generator:

You may use these links to get the program (version 0.13) and testdata:

The generator script is called from the command line and needs an installed Ruby interpreter to do its work. Execute it by simple typing in its name in a (Linux/Unix) shell like "./sfg.rb" or by invoking the Ruby interpreter with this script by "ruby sfg.rb". If you call it without or with arguments "-h" or "--help" you get this help text:

stefan@AMD64-X2 ~/foo $ ./sfg.rb --help sfg.rb -- yet another footprint generator for gEDA/PCB Version: 0.12 (08-JUN-2009) Author: S. Salewski License: GPL This is a plain footprint (land pattern) generator for gEDA/PCB written in Ruby. The intention was to make its use simple, safe and intuitive. Extension for new types of footprints is easy. The program processes a textual input file, which contains the parameters needed for generation of footprints. Each line of this input file defines a single parameter, i.e. "pindiameter = 0.8 mm". The input file is divided in sections by "Device = " statements. You can define global parameters, if you prepend the parameters with the line "Device = Global". Parameters specific for a special type of footprint are defined if you prepend the parameter definition by a command like "Device = DIP". In this case all following parameter definitions are local. You may redefine global parameters here, but after next "Device = " command all global parameters have again their previous state (and no local parameters exist). This behaviour ensures that insertion of a new section can never influence existing sections. You can define a default unit, so mm or mil for dimensions is optional. Equal sign for assignment is optional too, or you may uses ":=". Numeric parameters can be simple expressions like "2.1+0.8*2". If parameters are not numeric and are not simple text strings, you should include it in quotation marks. The command "Generate" followed by a filename will write the footprint file to disk. This is a small piece of a configuration file: Device Global date "10-APR-2008" clearance 10 mil defaultunit mm Device DIP defaultunit mil # locally overwrite a global parameter width = 300 pins 8 drilldiameter 0.8*1.1 mm # 10 % tolerance refdespos upperleft Generate "DIP8-300.fp" # this is a command, so do not use = sign. If you execute this program with argument -h or --help then this documentation is written to stdout. If you give a command line parameter, this is considered as an input file and processing starts. You can generate an empty input file (template) if you give "PrintAll" as command line argument, or you may generate an input template for a specific device by using that name, i.e. "DIP" as argument. Redirect the output to a file and fill in the missing information. (If you don't need the comments, then use sed to filter the output, like "./sfg.rb List | sed s'\ #.*\\'".) Supported device types: ----------------------- DIP: http://en.wikipedia.org/wiki/Dual_in-line_package SIP: Single In Line QFP: http://en.wikipedia.org/wiki/QFP CAPPR: Capacitor Polarized Round TRIMR: Potentiometer or variable Capacitor, 3 pin through hole with Round outline

This should be enough information to use it. If you give the command line argument "List" you get something like this:

stefan@AMD64-X2 ~/foo $ ./sfg.rb List Device = Global author = "" dist-license = GPL use-license = unlimited defaultunit = "" # mm or mil silkwidth = 10 mil # thickness of silk lines silkbox = "" # inner or outer for autosize, custom for explicit size, otherwise no box silkboxwidth = 0 mil # silkbox width, used if silkbox = custom, no box if value too small silkboxheight = 0 mil # silkbox height, used if silkbox = custom, no box if value too small silkoffset = 10 mil # distance between pads/pins and silk lines, ignored if silkbox = custom textpos = upperleft # position of reference designator, upperleft, few devices accept center textorientation = horizontal # horizontal, some devices may accept vertical refdessize = 100 # size of reference designator, default is 100 (integer) mask = 6 mil # distance between the copper of pads/pins and the mask clearance = 10 mil # distance between the copper of pads/pins and any polygon p1silkmark = "" # mark pin/pad 1 with silk: to get a mark use: mark, p1mark, yes, true, 1 p1coppermark = "" # mark pin/pad 1 with copper: to get a mark use: coppermark, yes, true, 1 Device = DIP pins = # total number of pins width = # separation of the two columns of pins -- center to center pitch = # distance between adjacent pins pad-dia = # outer diameter of copper annulus drill-dia = # diameter of the hole ovalpads = "" # to get ovals use: oval, ovalpads, yes, true, 1 p1silkmark = "" # mark pin/pad 1: global, or specific shape: semicircle, notch, damage, slash p1coppermark = "" # mark pin/pad 1: global section, or for specific shape: square, octagon # Generate ?.fp Device = QFP pins = # total number of pins rows = 0 # number of pins at side of pin one -- 0 is identical to pins/4 width = # separation of the two columns of pads -- center to center. If 0 height is used. height = # separation of the two rows of pads -- center to center. If 0 width is used. pitch = # distance between adjacent pads -- center to center padthickness = # should be smaller than pitch padlength = ovalpads = "" # to get ovals use: oval, ovalpads, yes, true, 1 p1silkmark = "" # mark pin/pad 1: global section, for specific shape: circle, damage, slash # Generate ?.fp

Redirect this output to a file, fill in the missing data, and use it as the input file for the generator. If all goes well this should result in fine footprint files similar to this one:

Element["" "" "DIP8_OvalPads" "" 0 0 -19650 -27150 0 100 ""]

(

Pin[-15000 -15000 6299 2000 7499 3937 "1" "1" ""]

Pad[-16575 -15000 -13425 -15000 6299 2000 7499 "1" "1" "onsolder"]

Pin[-15000 -5000 6299 2000 7499 3937 "2" "2" ""]

Pad[-16575 -5000 -13425 -5000 6299 2000 7499 "2" "2" "onsolder"]

Pin[-15000 5000 6299 2000 7499 3937 "3" "3" ""]

Pad[-16575 5000 -13425 5000 6299 2000 7499 "3" "3" "onsolder"]

Pin[-15000 15000 6299 2000 7499 3937 "4" "4" ""]

Pad[-16575 15000 -13425 15000 6299 2000 7499 "4" "4" "onsolder"]

Pin[15000 15000 6299 2000 7499 3937 "5" "5" ""]

Pad[13425 15000 16575 15000 6299 2000 7499 "5" "5" "onsolder"]

Pin[15000 5000 6299 2000 7499 3937 "6" "6" ""]

Pad[13425 5000 16575 5000 6299 2000 7499 "6" "6" "onsolder"]

Pin[15000 -5000 6299 2000 7499 3937 "7" "7" ""]

Pad[13425 -5000 16575 -5000 6299 2000 7499 "7" "7" "onsolder"]

Pin[15000 -15000 6299 2000 7499 3937 "8" "8" ""]

Pad[13425 -15000 16575 -15000 6299 2000 7499 "8" "8" "onsolder"]

ElementLine[-19650 -19650 -19650 19650 1000]

ElementLine[-19650 -19650 19650 -19650 1000]

ElementLine[19650 19650 19650 -19650 1000]

ElementLine[19650 19650 -19650 19650 1000]

ElementArc[0 -19650 3930 3930 0 180 1000]

Attribute("name" "DIP8_OvalPads")

Attribute("author" "Stefan Salewski")

Attribute("dist-license" "GPL")

Attribute("use-license" "unlimited")

Attribute("date" "08-FEB-2009")

Attribute("documentation" "www...")

)

One important note: The generator program is not much tested now. If you use it, carefully investigate the results, i.e. load the generated footprints into PCB program and make a printout. Arrange the electronic devices over the corresponding footprints to verify that they fit well. And verify the pin numbers inside of the PCB program. Please let me know if there are any problems.

Currently the program supports the basic types "DIP", "SIP" and "QFP". Expanding it to new types is not difficult: Expand the "datas" array which holds information for all devices, make a copy i.e. of the "GenDIP()" generator function, modify and rename it. And expand the function "Generate()" to call this new function. Some basic knowledge of the Ruby programming language and of the structure of PCB footprint files is sufficient to do this.

If you want to get some feeling of Ruby I recommend this fine tutorial:

If you want to learn the format of PCB footprint files, you may consult the really verbose description of Stuart Brorson:

Or you may read my short summary: